TECHNOLOGY

Freezing

Freezing is removal of heat from a substance until it attains sub zero temperatures and assumes a hard consistency by the solidification of its water content, both free and combined and hardening of the organic tissues.

I. Factors which affect freezing time:

The following factors affect freezing time of products.

- Freezer type

- Freezer operating temperature

- Refrigeration system and operating condition

- Air velocity in an air blast freezer

- Product temperature

- Product thickness

- Product shape

- Product contact area and density

- Product packing

- Species of fish

Types of Freezers:

a). Air Blast Freezers

In an air blast freezer, fish is frozen in a stream of high velocity cold air either in a batch or continuously, typically in a duct or tunnel in which a stream of cold air is guided over the product on shelves (batch) or on a conveyor (continuous air blast freezer); also called blast freezer/freezing tunnel/tunnel freezer. The advantage of the blast freezer is its versatility. It can cope with a variety of irregularly shaped products and whenever there is a wide range of shapes and sizes can be frozen.

Continuous air blast freezers: In this type of air blast freezer, the fish are conveyed through the freezer (trolleys or they may be loaded on a continuously moving belt or conveyor) usually entering at one and leaving at the other.

Batch air blast freezers Batch air blast freezers use pallets, trolleys or shelf arrangements for loading the product. The freezer is fully loaded, and when freezing is complete, the freezer is emptied and reloaded for a further batch freeze.

b). Plate freezers

In a contact freezer or plate freezer the fish is frozen by direct contact with a refrigerated surface, typically between two hollow metal plates cooled by a refrigerant, such that the distance between the plates can be varied up to 100 mm or more. One type in which fish, especially in flat packs such as laminated blocks, is frozen between two or more hollow, horizontal, parallel plates through which refrigerant passes is known as a horizontal plate freezer. In a vertical plate freezer, the refrigerated, parallel plates are vertical and it is used mainly at sea or onshore for freezing large 25 or 50 kg blocks of whole, gutted, or headed and gutted fish.

- Horizontal plate freezers

The Products are simply placed into the Horizontal pockets between the aluminum freezing plates in batches; the plates fall horizontally to give true double contact freezing. Once the freezing cycle is completed, the plates are lifted and opened, and then the product can be unloaded; after fresh product is loaded, the whole cycle can be continuous.

- Vertical plate freezers

The main advantage of this type of freezer is that fish can be frozen in bulk without the requirement to package or arrange on trays. The plates form what is in effect in bin with an open top and fish are loaded directly into this space. This type of freezer is therefore particularly suitable for bulk freezing and it has also been extensively used for freezing whole fish at sea in factory vessels. In most cases, fish can be loaded between the plates without wrappers and water need not be added either to strengthen the frozen block or improve the contact with the plates.

- IQF freezer

Individual Quick Freezing usually abbreviated IQF is a freezing method used in food processing industry. Products commonly frozen with IQF technologies are typically smaller pieces of food products. The short freezing prevents formation of large ice crystals in the product’s cells, which destroys the membrane structures at the molecular level.This makes the product keep its shape, colour, smell and taste after defrost, at a far greater extent.

Another significant advantage of IQF technology is its ability to separate units of the products during freezing, which produces higher quality product compared to block freezing. This advantage is also important for food sustainability, as the consumer can defrost and use the exact needed quantity. There is a range of IQF technologies, but the main concept is to transport the product into the freezer with the help of a processing line belt or infeed shaker. Inside the freezer, the product travels through the freezing zone and comes out on the other side. Product transportation inside the freezer is by different technologies. Some freezers use transportation belts similar to a conveyor belt. Others use bed plates that hold the product, and an asymmetrical movement makes the plate advance by itself through the freezer

4.Brine Freezer

Brine Freezers are used for quick freezing of Shrimps, Shell Fish and Crabs etc. With the Brine Freezer rapid freezing is obtained with minimum weight loss.

- Immersion Batch Immersion Freezing by means of submerging the product into agitated brine by the means of a hoist system. In the batch brine freezing process, the products are packed in plastic or stainless steel baskets, placed in racks with several trays, which are immersed into the brine, after which each product goes through a freezing process. The stainless steel baskets with the products are lowered into the tanks with the salt brine by forklift or fixed monorail crane system.

- Continuous Immersion System Immersion Freezing by means of submerging the product into agitated brine by the means of a conveyor system. The product is then drained before entering a Hardening Tunnel for deep/full freezing.

- Continuous Shower System Products are placed onto the moving conveyor belt and led past multiple spray nozzles which sprays cold brine to bring the temperature of products down at a rapid rate. In this process, both tray products and IQF products can be frozen. The product is then drained before entering a Hardening Tunnel for deep/full freezing.

Accelerated Freeze Drying (AFD):

Freeze-drying is a kind of preservation technology, by which the material is cooled below its eutectic temperature or glass transition temperature firstly to be solidified completely, then dried in vacuum space at low temperature by sublimation drying and desorption drying till 95-99% of moisture is removed. The product can be stored at room temperature or 4o-C for long time. Freeze-drying has become a most important technique for the preservation of heat- sensitive pharmaceuticals and foods.

In Accelerated Freeze-drying, food is held between two layers of expanded metal mesh and subjected to a slight pressure on both sides. Heating is by conduction, but heat is transferred more rapidly into food by the mesh than by solid plates, and vapour escapes more easily from the surface of the food. Both mechanisms cause a reduction in drying times compared with contact methods.

AFD Equipment

Fish Drying

Drying involves the removal of water content from the fish body.Generally two terms are now being commonly used in the drying of fish viz. “sun drying” and “dehydration”. These two are both the methods of preserving fish, almost similar but with little differences. In Sun-drying this process is carried out by exposing target fish directly under the sun. This is usually done in the open air using solar energy to evaporate the water content in the fish. Natural air carried away the evaporated water from the fish body. Dehydration, almost the same as sun drying, except that this process is practiced under controlled operational parameters like air temperature, relative humidity, air velocity, etc. A common practice is to dry fish in an enclosure provided with facilities to control these parameters.

Solar Fish Dryer

hrimp is cooked in order to produce changes in the texture and flavour of the product and to kill pathogenic microorganisms. Heating to an internal temperature above 66°C or 150°F (i.e., pasteurization conditions) is sufficient to kill the most resistant microorganisms. The boiling time should be long enough to develop fully the flavour and texture of the shrimp meat, and to loosen the meat from the shell; overcooking can destroy the flavour and can cause loss of weight. Cooking time is important; about 3 minutes is usually sufficient for shrimp, but the precise time for a certain size or quality of shrimp should be determined by experiment.

Shrimp Cooker

Chilling is a process by which the temperature of the fish is lowered to a point near freezing but not below it by means of heat withdrawal. The freezing point for different fish species varies between -0.6 and -2.2˚C and depends on the concentration of the cell fluids. It is usually taken as equal to -1˚C. Fish and fishery products processed in this way are called chilled products. Icing is one kind of chilling method. The high heat absorption capacity of ice makes it an ideal medium for the chilling of fish. The icing of fish is very easy that does not involve sophistication or a high level of skill. Ice is available almost everywhere in the country and the fish can be kept for 20-30 days in acceptable quality if proper icing and re-icing is done. The use of ice can substantially reduce post-harvest losses and improve the quality of fish.

Chilled fish in Flake ice

Live Seafood

Live fish is preferred by many markets especially in the South East Asia and China. Many consumers are ready to pay a premium price if the seafood is in live condition. Live and fresh fish and seafood are extremely dependent on the transit environment to maintain their optimum selling condition and avoid mortality. Special packing systems should be employed to avoid temperature abuse and counteract rough handling. Selecting high quality product for air shipment adds extra assurance that the product will arrive in a condition acceptable to the buyer. Product handling that assures high quality should begin on the fishing vessel or at the fish farm. Quality levels will also depend on natural factors including seasonal changes, particular harvest areas, feeding behavior, sex and spawning condition of the fish and seafood. Harvest methods and onboard handling factor greatly in maintaining product quality and freshness. When shipping live fish and seafood, there are a number of species-specific factors that must be considered to ensure that the product arrives alive. These factors include 1) respiratory rates; 2) ability to handle stress; 3) excretory functions, and; 4) temperature tolerance ranges. Live oysters, mussels, crabs, whelks, and lobsters are always considered as a delicacy.

LIVE MUD CRAB

Canning is a relatively modern technology which enables man to preserve food in an edible condition under a wide range of storage conditions for long periods – from a few months to several years. Essentially, the process involves hermetically sealing the food in a container, heat ‘sterilising’ the sealed unit, and cooling it to ambient temperature for subsequent storage. Canned fish is famous for the way it is packed so tightly within the container, leaving very little space for additional liquids.

Filling and sealing

Fish, being a physically delicate food and, therefore, easily damaged and fragmented by mechanical handling operations, are still largely packed into cans or other retortable containers by hand, with brine, edible oil or sauce which may be metered in mechanically. Often, the fish, after the usual heading, gutting, cleaning, and trimming operations, are subjected to pre-processing operations such as salting, brining, drying, smoking, cooking, or a combination of these. Such pre-processing operations have the advantages of:

(a) denaturing the proteins and thus rendering the fish muscle firmer and more capable of withstanding handling during the filling operation; and

(b) removing water from the fish makes them less subject to shrinkage and unsightly aqueous exudation inside the can during heat treatment.

CANNED TUNA

Retort Pouch A retort pouch is constructed from a flexible metal-plastic laminate that is able to withstand the thermal processing used for sterilization. The food is first prepared, either raw or cooked, and then sealed into the retort pouch. The pouch is then heated to 240-250°F (116-121°C) for several minutes under high pressure inside a retort or autoclave machine. The food inside is cooked in a similar way to pressure cooking. This process reliably kills all commonly occurring microorganisms (particularly Clostridium botulinum), preventing it from spoiling. The packaging process is very similar to canning, except that the package itself is flexible. The lamination structure does not allow permeation of gases from outside into the pouch. The retort pouch construction varies from one application to another, as a liquid product needs different barrier properties than a dry product, and similarly an acidic product needs different chemical resistance than a basic product. Some different plastic layers used in retort pouches include:

- Polyester (PET) – provides a gloss and rigid layer, may be printed inside

- Nylon (bi-oriented polyamide) – provides puncture resistance

- Aluminum (Al) – provides a very thin but effective gas barrier

- Food-grade cast polypropylene (CPP) – used as the sealing layer

- Polyethylene (PE) – can be used instead of PP as a sealing and bonding layer

This multi-layer structure prevents the retort pouch from being recycled into other retort pouches or food packaging. However, the material can be recycled into an aluminized resin or up-cycled into textile materials. The weight of a pouch is less than regular cans or bottles, and the energy required to produce each pouch is less than competing packaging from metals, paper, and glass.

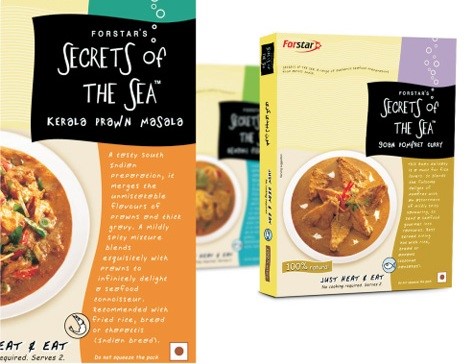

Seafood Curry in Retort Pouches

The principal methods of drying, or dehydrating, fish are by sun drying, forced-air drying, vacuum drying, or vacuum freeze-drying. Each of these methods involves adding heat to aid in the removal of water from the fish product. During the initial stages of drying, known as the constant-rate period, water is evaporated from the surface of the product and the temperature of the product remains constant. In the final stages of drying, known as the falling-rate period, the temperature of the product increases, causing water to move from the interior to the surface for evaporation.

Surimi

Surimi is a crude myofibrillar protein concentrate prepared by washing minced, mechanically deboned fish muscle to remove sarcoplasmic constituents and fat, followed by mixing with cryoprotectants (usually polyols) to prevent protein denaturation during frozen storage. Surimi is usually block brozen using plate freezers. Good quality surimi is odorless and has a creamy white appearance. Surimi has excellent gelling properties so that it can be formed into various shapes. Originating in Japan several centuries ago, surimi is a uniquely functional food ingredient made of fish proteins and used in surimi based seafood products. Surimi analogues or Surimi seafood consists of unique seafood products with added convenience, safety and versatility having a flavor similar to that of naturally occurring crab, shrimp, lobster and other shellfish. Surimi seafood is formed by mixing surimi with various food ingredients, which subsequently formed into various shapes before cooking and setting the gel structure of the final product. During the manufacturing, various flavors are added to give the food its recognizable character and hence called analog products. Surimi seafood is vacuum-packed and pasteurized to destroy harmful bacteria (pathogens). Most retail products are both fat-free and low in cholesterol. They are often nutritionally enhanced with the inclusion of omega-3 oil.